Visit us at the NASTT No-Dig Show 2023 in Portland, Oregon

Metaflo Technologies is attending the NASTT 2023 No-Dig Show, largest trenchless technology conference in North America, where thousands of professionals attend to learn new methods and techniques that will save money and improve infrastructure.

Read MoreGame-Changing Polymers – Trenchless Article

Recently, Trenchless Technology Magazine published an article in their 2021 HDD Guide, written by Andrew McNabb, President & COO at MetaFLO, on the increasing demand for effective liquid waste disposal solutions. In this blog post, we’ll break down the article’s key takeaways.

Read MoreCan underground infrastructure improvements for transportation be cost-effective and environmentally friendly?

As cities continue to grow and expand, there is an increased need for investment in transportation infrastructure. Transportation infrastructure is not as simple as building new roads and subways, it requires a lot of planning and engineering.

Read MoreThe Demand For Hydro Excavation is Booming

The Hydro Excavation (Hydrovac) market experienced a surge in the last half decade. According to Global Hydrovac Trucks Market’s 2021 research report, the Hydrovac trucks market is expected to continue rising significantly from 2021 to 2026.

Read MoreMetaFLO’s Reagents Will Help You Comply With Ontario’s New Excess Soil Regulations

All across Canada, municipal and provincial governments have been adjusting regulations pertaining to excess soils. This is largely due to recognition of soil as a valuable commodity. Soil provides habitats for organisms, filters and stores water, supports plant growth, and even more.

Read MoreLiquid waste is a necessary byproduct of many industrial projects … expensive transportation and disposal doesn’t have to be!

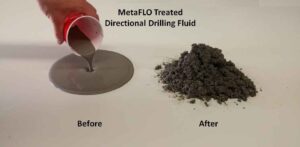

MetaFLO reagents turn liquid waste into a stackable solid in real time while adding only 1/2 of 1% of the liquid waste volume. A proprietary reagent chemistry, MetaFLO reagents replace the need for many common and more costly alternatives like Portland cement, sawdust, lime, fly ash and others giving you an easy, quick and environmentally friendly way to manage your liquid waste streams.

Read MoreSales Engineer, John Hayes, Joins the MetaFLO Team

John has joined our team as a Sales Engineer and is based in Houston, Texas. John will be focusing on growing MetaFLO’s revenue in the US market as well as supporting existing clients, service providers and distributors.

Read MoreMetaFLO is Attending The UCT Conference & Exhibition

On July 13th, MetaFLO Technologies will be attending the Underground Construction Technology Conference & Exhibition. Read on to learn more about the event and how you can connect with us at UCT.

Read MoreDelving Into the Science Behind Solidification

Solidification of liquid waste streams, including drilling mud, wet hydro excavation material and tunneling spoils, started out as a very rudimentary process. Dry material (i.e. dry dirt) would be added to wet material (i.e. drilling mud) in order to get a dry (solid) material that was suitable for transportation and disposal.

Read MoreInnovation in Stormwater Pond Maintenance

The ponds you pass every day on your way to work or walking your dog in the evening are not typically spring fed, naturally occurring bodies of water left behind by receding mini glaciers from the last Pleistocene epoch. These ponds have been engineered in housing and commercial areas as a tool to manage water and capture particulate debris from snow melt and rain events.

Read More