Why choose MetaFLO

for liquid waste management?

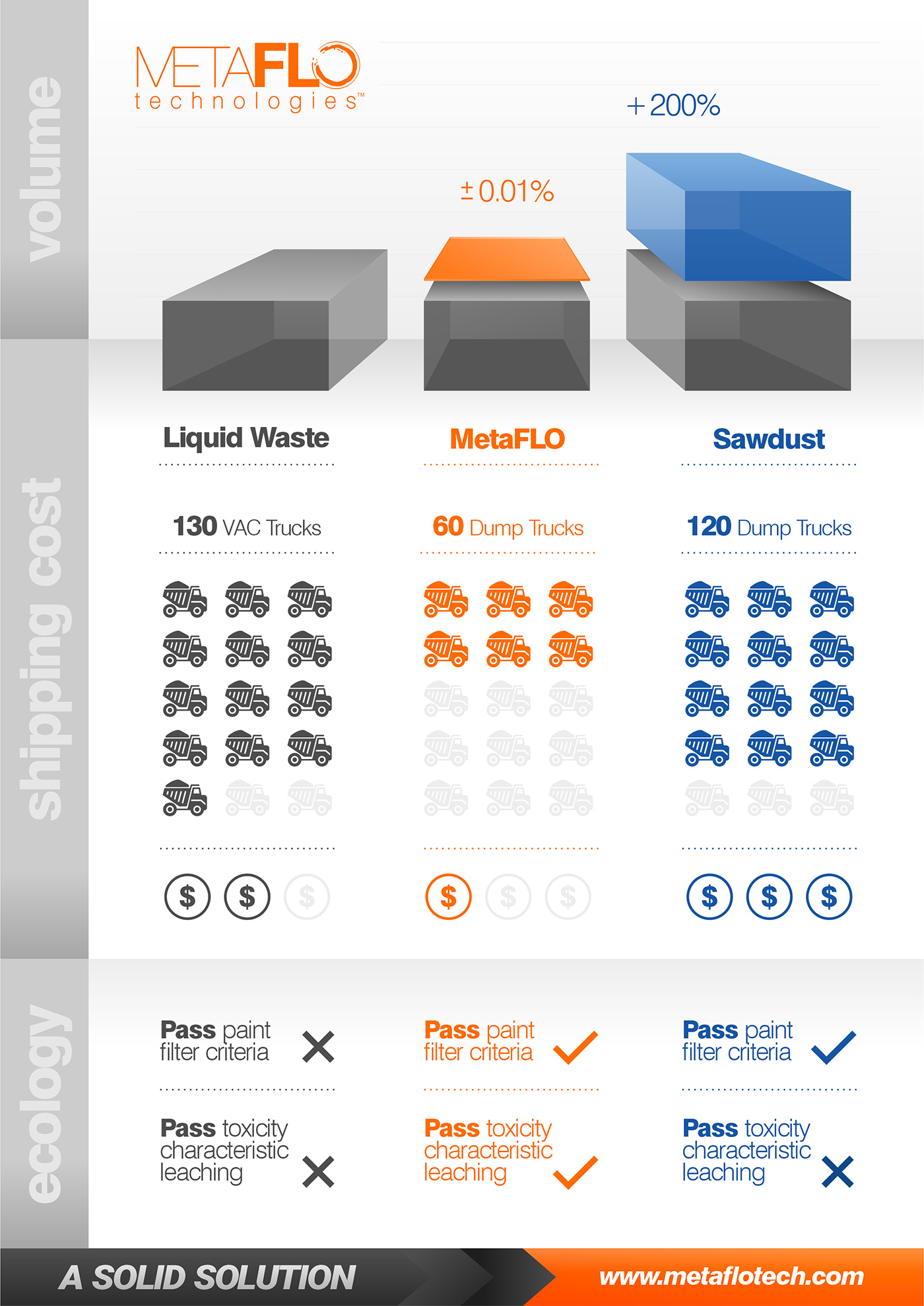

MetaFLO’s advanced chemistry turns liquid waste into a stackable solid in real time. Our proprietary reagent formula solidifies the same amount of liquid but without creating excess volume (bulking), making disposal easier, more efficient and less costly. Simply put: less waste, lower transportation and disposal costs, improved safety, better control and compliance while significantly reducing GHG emissions

MetaFLO is a practical, cost effective and sustainable options

Conventional liquid waste disposal techniques add amendments like Portland, fly-ash, lime or sawdust to meet solids criteria for transportation to landfill – expanding volume by up to 200%. MetaFLO’s engineered reagents typically require a dosage of only 0.5%.

Why use MetaFLO

- MetaFLO reagents are fast – Immediately converts liquid waste to a solid in minutes

- MetaFLO reagents are easy – Creates a dry, stackable solid for easy handling

- MetaFLO reagents produce minimal bulking compared to common alternatives

- MetaFLO reagents meet standards

- Helps waste pass Toxicity Characteristic Leaching Procedure (EPA Method 1311)

- Helps waste pass paint filter criteria (EPA 9095)

- Landfill friendly and does not biodegrade

- MetaFLO reagents are environmentally friendly

- Non-Hazardous

- Non-Toxic

- Chemically Inert

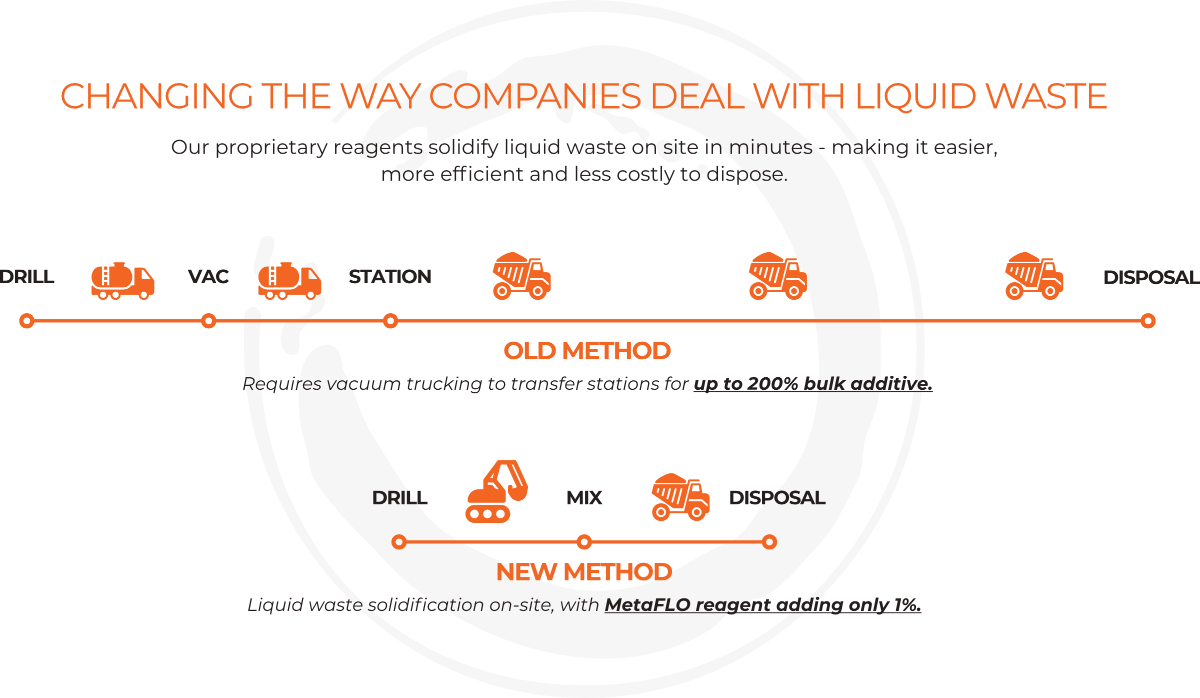

Conventional Liquid Waste Disposal vs. MetaFLO’s On-Site Liquid Waste Disposal

MetaFLO’s On-Site Liquid Waste Disposal (Solidification)

- Transportation for disposal requires 60 dump trucks

- Waste shipped to final disposal site

- Reduced risk due to 54% fewer trucks and NO liquid transport

- More control of waste and compliance for client

- Approx 33% cost savings in this example

- 63% reduction in Greenhouse Gas Emissions (C02 eq.)*

- Soil reused as clean, regenerative fill material at local aggregate site

Conventional Liquid Waste Disposal (No Solidification)

- Transportation for disposal requires 130 vac trucks

- Waste shipped to licensed transfer station

- Increased risk due to transporting liquid

- Less control of waste and compliance for client

- Higher cost due to more vac trucks required to dispose of waste (paid at a higher price compared to dump trucks)

- Higher greenhouse gas emissions due to more trucks having to transport waste

- Waste cannot be land applied for beneficial re-use.

MetaFLO’s Technology can Yield Significant Cost Savings

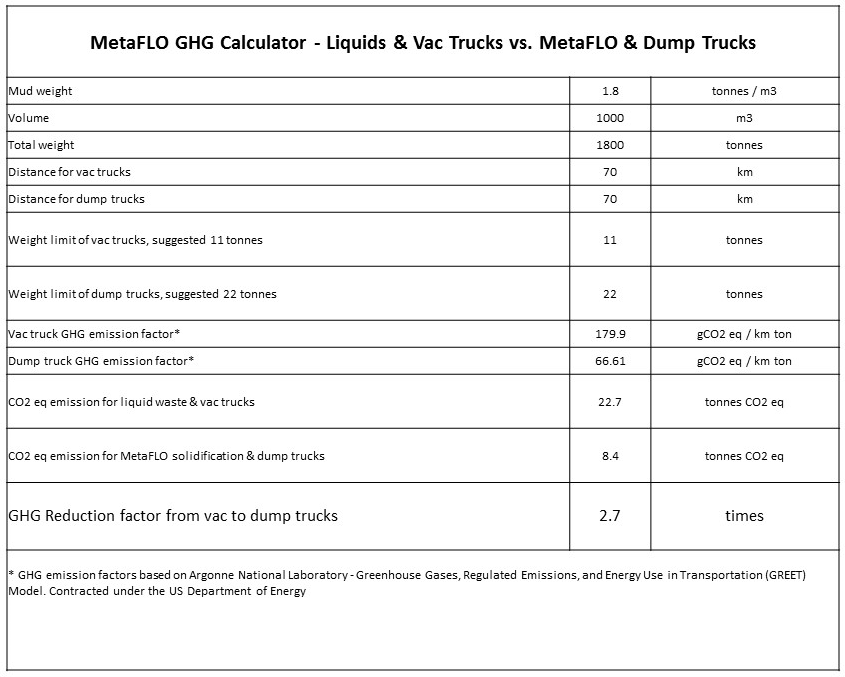

MetaFLO’s Technology has a Reduced Environmental Impact

Our solidification methods use extremely low dosages of reagent to achieve regulatory solids criteria – often less than 1% wt/wt. The low dosage adds less weight to the source waste than what is lost through natural evaporation after treatment resulting in a net reduction in total waste. Dump trucks can now be utilized to transport the solidified material to the appropriate disposal site far more efficiently than relying on vacuum trucks to transport liquids to treatment facilities. Additionally, liquid waste receiving sites are more scarce in most jurisdictions resulting in longer drives and greater cost associated with turn-around times. The table below illustrates how more trucks and greater drive times cause significant and unnecessary additional carbon emissions.